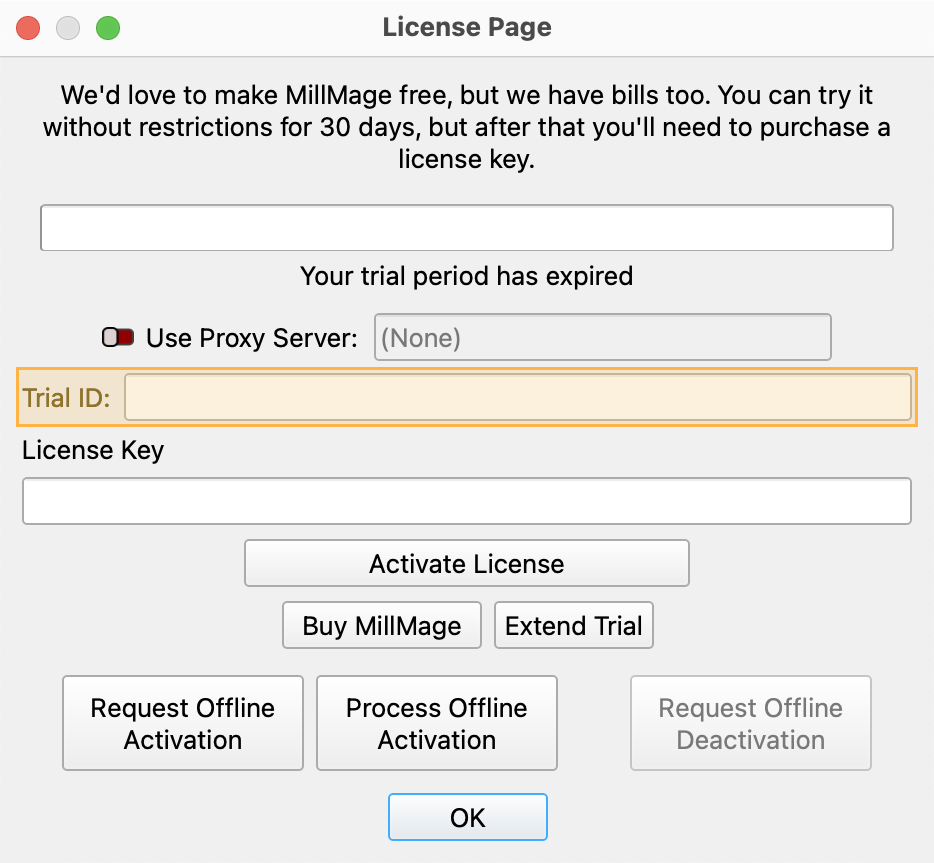

Trial Period or Updates Expiring? Email Trial ID to Support

Thank you for testing MillMage!

Release Candidate users who see a "Your trial period has expired" notice when opening MillMage can request an extension to the update period by emailing the MillMage Trial ID to the Support team.

Find your Trial ID in the License Management window. Email your Trial ID to Support@MillMageSoftware.com to start your request. The duration of the extended update period may vary.

Warning

The current version of MillMage is a Release Candidate — a stable version of software that is nearly ready for official release, but in need of additional public testing. Please report any unexpected behavior in the MillMage Software Questions section of our forum, including screenshots and as much detail as possible. Ask hardware compatibility questions in the MillMage Hardware Compatibility section.

Users new to MillMage should follow the Getting Started guide.

Video: How to Use a Release Candidate

This video features our sister software, LightBurn. While there may be slight differences in appearance and layout, the demonstrated processes are similar in MillMage.

Warning

This documentation is in active development and in a prerelease state. These documents are not complete and may include missing pages, broken links, and placeholders. Content is being updated as feedback is reviewed. Your patience is appreciated.

Adding Your Machine

Consult Manufacturer Instructions

Always consult the documentation that came with your CNC machine, or the manufacturer's online resources, before beginning the device setup process. Some manufacturers provide settings bundles, importable device profiles, device drivers, or special setup instructions that are necessary to fully utilize their machines with MillMage.

Add a CNC Machine to MillMage¶

-

The first time you open MillMage after a new or clean installation, you'll be greeted by the Help and Notes window with information on your next steps, helpful tips, and program details. Read the notes and select Okay to close the Help and Notes window.

-

New users can dismiss the Compatibility Warning window by selecting OK.

Existing MillMage User?

Users testing early Beta and Release Candidate builds must delete and recreate all devices starting with version 0.8 build RC-1 to prevent failure and errors. Do not import existing device profiles created before v0.8 RC-1.

-

The Devices window will automatically open next and will display an empty list of devices, along with options for creating a device profile at the bottom. You need to have at least one device profile created in order to use MillMage — if you close out of this window without creating one, you'll see a warning message with the option to go back and set up a device, have MillMage automatically create a dummy machine profile for you, or close out of the software.

Create a placeholder device if you don't yet have a CNC machine. Having a CNC machine present or connected is not required to use the design and machining operation tools in MillMage.

Need to Reopen the Devices Window?

Open the Devices window anytime by clicking on the Devices button found in the Job Control window, or by selecting CNC Tools → Manage Devices.

-

Select Create Manually to launch the New Device Wizard.

-

Select how you will connect your CNC machine to MillMage. Select Continue to move forward and Go Back to return to the previous step in the wizard.

Most CNC users will use a USB cable and will choose Serial/USB as the connection type.

-

Enter a name for your CNC machine, select the Device Units of Measure, and enter the CNC machine work area dimensions, in the units you selected.

Refer to the documentation that came with your CNC machine if you're unsure of the correct dimensions. You can update these values anytime in the Device Settings window.

-

Set Machine Zero Location¶

Machine vs Project Zero

It is important to choose the correct machine homing location, or the position the tool is moved to when commanded, as MillMage needs to know the physical setup of your CNC machine to match the project/work coordinate space to your machine coordinate space and establish the 0,0,0 (X, Y, Z axis) coordinates within your machine's working area.

The homing location will vary between CNC machine brands and models. Always refer to your CNC machine manufacturer's documentation to learn about the homing behavior of your specific device.

CNC machines equipped with hardware-based end stops will home, or move the tool along each axis towards each axis' zero point, when commanded to by CNC control software like MillMage.

CNC machines without hardware-based end stops using firmware-based travel limits will need to jog their tool to the recommended machine zero location. Always refer to your CNC machine manufacturer's documentation to learn about the homing behavior of your specific device.

Pick one of four corners of the X and Y axis in the Machine Zero Location setting that corresponds to the physical location your CNC machine homes to when commanded or when powered on. Many GRBL users can pick the Front Left corner. Most Shapeoko & Carbide 3D CNC machine users should choose the Rear Right corner.

-

-

Change the GCode flavor to match the GCode variation required by the machine. Refer to your device documentation for details.

Choose GCode Flavor¶

Choosing A Compatible GCode Flavor

Refer to your CNC manufacturer for details if you are unsure of your selection for GCode flavor.

Operators unsure of their controller's GRBL flavor can choose GRBL in the drop down to continue & should send the $l command in the console to verify their firmware type after finishing adding a device. Update the GCode flavor at any time in Device Settings.

GCode Flavor Notes GRBL Many small (3018) & desktop-class CNC machines are likely GRBL-based. Compatible with FluidNC firmware GRBL STM STM32-driven ARM devices grblHAL STM32, ESP32, MSP, TMC, RP2040, Arduino Due controllers — Extended Options support may vary Smoothieware Labs Feature — Known Issue: Press Stop after jogging to clear Busy status

Mach3 & Mach4 Users should review the Custom GCode blocks to make sure the defaults are correct LinuxCNC Also compatible with Mach3/Mach4 and Masso firmware UCCNC UC100, UC300, UC300ETH, UC400ETH and AXBB-E controllers Duet/RRF RepRap Firmware Masso Users should review the Custom GCode blocks to make sure the defaults are correct Generic Choose Generic if you need to define the Custom GCode blocks by hand for a full custom controller Optionally update the remaining features as relevant. Most users will not need to change anything in the Basic tab. Advanced users can add device support for optional accessories and features in the Advanced tab. Refer to the documentation that came with your CNC machine if you're unsure of the correct selections. Change these settings anytime in the Device Settings window.

Enabling Advanced Features and Customizations

If you're an advanced MillMage or CNC machine operator, use Custom GCode to customize features in MillMage to better manage your machine, workflow, and support your hardware accessories and features.

Update these advanced Custom GCode features after adding your machine by accessing them at Device Settings → Custom GCode.

-

Review the New Device Wizard summary and click Finish to finish adding a device to MillMage.

Set Default Device

If you have more than one device profile set up, you can mark a specific profile as your default device by selecting it in the list, then clicking Make Default → OK to finish. The default device name will be marked with an asterisk (*).

Next Steps¶

For more help using MillMage, please visit our forum to talk with MillMage staff and users, or email support.